Description

LVXING provides various of Stainless Steel Filter Cylinders and different shape Wire Cloth Filter Tubes.

1) According to shapes,these stainless steel filter tubes can be divided into straight cylinders,conical filter tubes,filter baskets,bowl shape filter tubes,dish shape filter tubes;

2) According to edge forming process,these filter tubes can be divided into copper edge wrapped filter tubes,stainless steel edge wrapped filter tubes,flanged edge filter tubes,threaded filter tubes,supporting rod filter tubes,handlebar filter tubes,spot welded edge,etc;

3) According to processing technology,these filter tubes can be divided into pleated filter cylinders,sintered filter tubes;

4) According to mesh fabric,they can be divided into expanded metal mesh filter cylinders,perforated filter tubes,etching mesh filter tubes,woven mesh filter tubes and integrated filter tubes;

5) According to layers,they can be divided into single layer filter cylinders and multilayed filter cylinders.

Specification

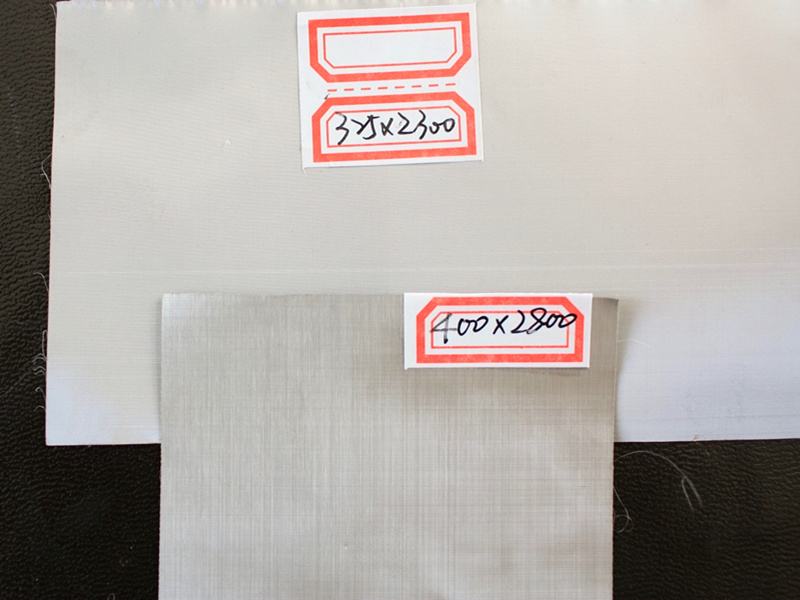

Material: AISI/SUS 304 304L 316 316L,904L,Copper,Monel 400,titanium,nickel,galvanized steel mesh,etc;

Size: Long or short,any diameter as customized.

Feature

1. It is durable and strong that makes the screen more effective for filtration;

2. No burr,no move wire,long service life;

3. It can be cleaned repeatedly and economically;

4. Large operating temperature range;

5. High flow rates at very low pressure drops;

6. Capacity of high dirt holding;

7. No chances of occurring media migration.

Application

These filter cylinders are more effective for polymer extrusion as polyester,polyamide,polymer,plastic blown,varnishes,paints;They also widely used as filters to separate sand or other fine particles from liquid in industrial or irrigation.

Tags: Stainless Steel Filter Cylinders,Wire Cloth Filter Tubes,Cylindrical Extruder Screen

1) According to shapes,these stainless steel filter tubes can be divided into straight cylinders,conical filter tubes,filter baskets,bowl shape filter tubes,dish shape filter tubes;

2) According to edge forming process,these filter tubes can be divided into copper edge wrapped filter tubes,stainless steel edge wrapped filter tubes,flanged edge filter tubes,threaded filter tubes,supporting rod filter tubes,handlebar filter tubes,spot welded edge,etc;

3) According to processing technology,these filter tubes can be divided into pleated filter cylinders,sintered filter tubes;

4) According to mesh fabric,they can be divided into expanded metal mesh filter cylinders,perforated filter tubes,etching mesh filter tubes,woven mesh filter tubes and integrated filter tubes;

5) According to layers,they can be divided into single layer filter cylinders and multilayed filter cylinders.

Specification

Material: AISI/SUS 304 304L 316 316L,904L,Copper,Monel 400,titanium,nickel,galvanized steel mesh,etc;

Size: Long or short,any diameter as customized.

Feature

1. It is durable and strong that makes the screen more effective for filtration;

2. No burr,no move wire,long service life;

3. It can be cleaned repeatedly and economically;

4. Large operating temperature range;

5. High flow rates at very low pressure drops;

6. Capacity of high dirt holding;

7. No chances of occurring media migration.

Application

These filter cylinders are more effective for polymer extrusion as polyester,polyamide,polymer,plastic blown,varnishes,paints;They also widely used as filters to separate sand or other fine particles from liquid in industrial or irrigation.

Tags: Stainless Steel Filter Cylinders,Wire Cloth Filter Tubes,Cylindrical Extruder Screen