Description

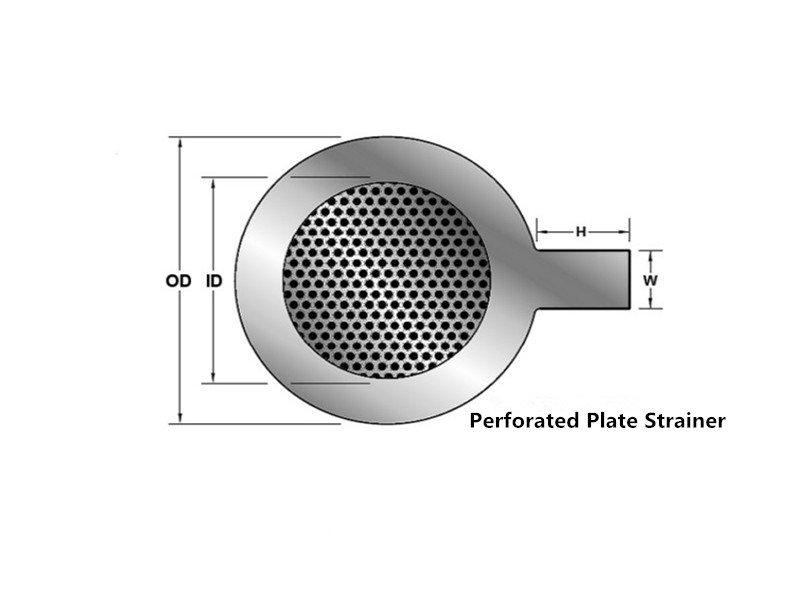

Temporary Basket Strainers have different styles,include flat bottom cone temporary strainers,cylindrical pipeline strainers with flange,special shape temporary strainers,etc.These temporary strainers are made of stainless steel perforated metal mesh and inner woven wire cloth,it installed inside the fluid production line to process filtration and protect the pumps,meters,valves and other mechanical components from the impact of certain matters that are processed through the system.

Specification

Material: Stainless steel 304 304L 316 316L,etc.

Shape/types: Flat bottom cone strainers,cylindrical pipeline strainers with flange,other shape as customized;

Filter Media: Perforated metal mesh + Stainless Steel Wire Cloth

Layers: One layer perforated metal mesh with no inner wire cloth,single layer wire cloth or multilayer wire cloth.

Feature

1. It belongs to the pipeline coarse filtration series and has simple structure;

2. Easty to clean and replace.When clean needed just take it out and reinstall after cleaning;

3.Stainless steel material is corrosion resistance,long service life;

Application

1. The principle is that when the fluid enters the conical filter,its impurities are blocked and the clean fluid flows out of the outlet;

2. Remove the impurities in the medium of the pipeline,make the equipment work normally, achieve a stable process,and ensure the safety of equipment production;

3. It is mainly used for boiling, drying, conveying and filtering of solid particles in pharmaceutical,chemical,pesticide and food industries.

Specification

Material: Stainless steel 304 304L 316 316L,etc.

Shape/types: Flat bottom cone strainers,cylindrical pipeline strainers with flange,other shape as customized;

Filter Media: Perforated metal mesh + Stainless Steel Wire Cloth

Layers: One layer perforated metal mesh with no inner wire cloth,single layer wire cloth or multilayer wire cloth.

Feature

1. It belongs to the pipeline coarse filtration series and has simple structure;

2. Easty to clean and replace.When clean needed just take it out and reinstall after cleaning;

3.Stainless steel material is corrosion resistance,long service life;

Application

1. The principle is that when the fluid enters the conical filter,its impurities are blocked and the clean fluid flows out of the outlet;

2. Remove the impurities in the medium of the pipeline,make the equipment work normally, achieve a stable process,and ensure the safety of equipment production;

3. It is mainly used for boiling, drying, conveying and filtering of solid particles in pharmaceutical,chemical,pesticide and food industries.

|

DN |

Installation dimension

|

Effective filtration area(m2)

|

Weight(Kg)

|

|||||||

|

d

|

|

|

|

PN0.6

|

PN1.0

|

PN2.5

|

||||

|

PN0.6

|

PN1.0

|

PN2.5

|

I

|

h

|

t

|

|||||

|

20

|

.

|

.

|

.

|

.

|

.

|

.

|

.

|

.

|

.

|

.

|

|

25

|

62

|

70

|

70

|

46

|

90

|

2

|

0.00094

|

0.07

|

0.08

|

0.08

|

|

32

|

72

|

80

|

80

|

61

|

100

|

2

|

0.00177

|

0.08

|

0.10

|

0.10

|

|

40

|

84

|

90

|

90

|

66

|

120

|

2

|

0.00259

|

0.12

|

0.14

|

0.14

|

|

50

|

94

|

105

|

105

|

81

|

130

|

2

|

0.00460

|

0.14

|

0.17

|

0.17

|

|

65

|

114

|

125

|

125

|

91

|

140

|

2

|

0.00699

|

0.19

|

0.22

|

0.22

|

|

80

|

132

|

142

|

142

|

111

|

150

|

2

|

0.01030

|

0.26

|

0.30

|

0.30

|

|

100

|

152

|

162

|

162

|

141

|

160

|

2

|

0.01550

|

0.35

|

0.37

|

0.37

|

|

125

|

182

|

192

|

192

|

172

|

190

|

3

|

0.02479

|

0.63

|

0.70

|

0.70

|

|

150

|

206

|

218

|

218

|

202

|

210

|

3

|

0.03463

|

0.76

|

0.88

|

0.86

|

|

200

|

262

|

272

|

282

|

262

|

240

|

3

|

0.03379

|

1.19

|

1.30

|

1.40

|

|

250

|

316

|

326

|

340

|

322

|

270

|

3

|

0.09699

|

1.65

|

1.78

|

1.95

|

|

300

|

370

|

382

|

395

|

362

|

300

|

3

|

0.13594

|

2.18

|

2.34

|

2.53

|

|

350

|

420

|

438

|

454

|

404

|

340

|

6

|

0.17343

|

4.02

|

4.72

|

5.12

|

|

400

|

470

|

492

|

510

|

464

|

365

|

6

|

0.22476

|

4.96

|

5.89

|

6.41

|

|

500

|

575

|

590

|

616

|

564

|

430

|

6

|

0.34523

|

6.99

|

7.66

|

8.80

|

|

600

|

676

|

690

|

726

|

726

|

490

|

6

|

0.50199

|

9.49

|

10.22

|

12.1

|

Tags: Temporary Basket Strainers, Temporary Pipeline Strainers, Flat Bottom Cone Temporary Strainers